CNC Precision Engineering is at the core of delivering high-quality, reliable solutions for industries across the UK. Our team of expert engineers uses cutting-edge CNC machining technology to produce precision-engineered components that meet exact specifications. From CNC lathe, milling, programming and machining services our company covers a broad range of precision needs, catering to businesses of all sizes and sectors.

Our CNC precision engineering services include CNC turning, milling, and programming, all designed to ensure the utmost accuracy and quality across a vast range of parts and components. As one of the UK’s leading CNC engineering companies, we deliver precision components that align with the unique requirements of each project.

With a commitment to high standards in manufacturing, we serve industries with customised machining solutions, focusing on quality at every step. Whether you’re seeking advanced CNC precision engineering, detailed precision components, or reliable machining services, our expertise and dedication ensure your business achieves the exacting standards needed in today’s competitive manufacturing sector.

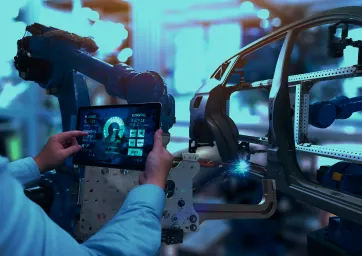

At our CNC precision engineering company, we specialise in delivering top-tier machining services designed to meet the high standards of businesses in the industrial and manufacturing sectors. With advanced CNC technology and a skilled team of engineers, we provide precision-engineered components tailored to your exact specifications. From complex components to high-volume production, we support a broad range of industries, including automotive, aerospace, and electronics, ensuring every part is crafted to meet rigorous quality and performance standards.

All optimised for precision and efficiency. Using state-of-the-art CNC machines, our expert engineers push the envelope when transforming raw materials into highly precise parts that maintain integrity and consistency, even under the strictest requirements. Each stage of our production service & maintenance process, from design to final analytics & inspection, is carried out with a meticulous focus on quality, so every component meets your specifications. Partnering with us means working with a trusted leader in CNC precision engineering, with a commitment to sustainable manufacturing practices and unparalleled quality assurance. Our CNC machining technology allows us to handle a wide range of materials and complexities, making us a versatile solution for companies seeking reliable parts for demanding applications. We work closely with our clients to ensure every aspect of the project, from planning to delivery, aligns with their objectives. With years of experience and expertise in precision engineering, we are a trusted provider of CNC machining solutions. Whether you’re a small business needing custom components or an established industrial company with high-volume demands, we deliver CNC precision parts and machining services that keep your business moving forward. Let us help you streamline production, reduce lead times, and enhance product quality, so your business thrives in today’s competitive industrial landscape.

Our mission is to provide exceptional precision, efficiency, and innovative solutions to meet your specific manufacturing needs.

At our state-of-the-art station, we focus on providing top-tier machining solutions for various industries, including aerospace, medical, automotive, and oil & gas.

Our engineers use advanced machine tools and CNC machines to perform precise machining processes. We specialise in vertical machining, utilising vertical machining centres that offer superior accuracy and efficiency. These machines feature multiple axes, allowing us to handle complex designs and high-precision components with ease.

Our machining centre is equipped with the latest software, including CAD and CAM systems, which enables us to program and design parts with utmost precision. This integration of technology ensures that our machines can carry out intricate machining tasks with minimal human intervention, improving overall productivity.We use a variety of tools tailored to different machining needs. Whether it’s cutting, drilling, or milling, our range of machine tools ensures each operation is carried out with optimal efficiency.

The ability to program machines directly from CAD files allows for faster setup times and smoother transitions from design to production. Our commitment to innovation and excellence in the manufacturing sector is evident through the adoption of cutting-edge technology. From design to final machining, we provide complete solutions that cater to the demanding requirements of industries like aerospace, medical, automotive, and oil & gas. The combination of skilled engineers, advanced machinery, and powerful software ensures that we can deliver high-quality parts that meet the most stringent standards in the industry.

At CNC Precision Engineering, we understand that the smallest details make the biggest difference. Our dedication to precision engineering ensures that every product we deliver meets the highest standards of accuracy and quality. Here’s why CNC Precision Engineering should be your go-to partner:

Leveraging state-of-the-art CNC machining technology, we achieve unparalleled accuracy in every project. Our expertise in CNC precision enables us to create intricate components with tight tolerances and complex geometries, ensuring that your specifications are met to the letter.

Aluminium is a versatile and widely used material in various industries. Our advanced CNC aluminum machining capabilities allow us to produce high-quality aluminium parts that are lightweight, durable, and precisely engineered for your applications.

We manufacture a wide variety of flanges, including standard and custom designs. Our flanges are crafted with meticulous attention to detail, ensuring a perfect fit and reliable performance in your systems.

Our specialised services include the production of spectacle blinds, spades, and spacers. These components are essential for isolating sections of piping systems for maintenance and safety purposes. We provide robust and precisely machined solutions that meet industry standards.

Our blanking spades are designed for secure and efficient isolation of pipelines. Manufactured with precision, these spades offer reliable performance and durability in demanding environments.

We thrive on innovation and tailor our services to meet your unique needs. Our team of experts collaborates with you to develop customised solutions that address your specific challenges and goals.

Our CNC machining services are renowned for their accuracy and efficiency. Utilising the latest CNC technology, we produce high-precision components with complex geometries and tight tolerances. Our capabilities include:

Allows for the creation of intricate parts with high precision.

Ideal for producing cylindrical parts with complex features.

From rapid prototyping to full-scale production runs, we deliver consistent quality and precision.

Our CNC aluminium machining services are designed to produce high-quality aluminium parts with consistent accuracy. We offer:

Tailored to meet your specific requirements.

Efficient production processes for large-scale manufacturing.

Knowledge of a wide range of aluminium grades to ensure optimal performance and durability.

We provide a comprehensive range of flanges for various applications. Our flange manufacturing services include:

Manufactured to meet your specific requirements.

Ensures a perfect fit and reliable performance.

Ability to work with various materials, including stainless steel, carbon steel, and more.

Our expertise in producing spectacle blinds, spades, and spacers ensures that your piping systems can be safely and efficiently isolated. We offer:

Tailored to meet your specific requirements and industry standards.

Ensures accurate dimensions and reliable performance.

Manufactured from high-quality materials for long-lasting use.

Our blanking spades are designed for secure and efficient isolation of pipelines. We provide:

Tailored to meet your specific needs.

Ensuring durability and reliability in demanding environments.

Guarantees accurate dimensions and a perfect fit.

CNC Precision Engineering is proud to serve a wide range of industries, each with its unique set of challenges and requirements.

The aerospace industry demands the highest levels of precision and reliability. Our expertise in producing components for aircraft, spacecraft, and defense systems ensures that we meet these stringent requirements. We provide:

Lightweight Components: Utilising advanced materials to reduce weight without compromising strength.

Complex Geometries: Precision machining of intricate parts with tight tolerances.

Reliability and Safety: Adhering to strict quality and safety standards to ensure the reliability of every component.

In the fast-paced automotive industry, precision and efficiency are crucial. Our services support the production of high-performance components for vehicles, including:

Engine Parts: Precision machining of engine components for optimal performance.

Chassis and Suspension: Manufacturing durable and reliable parts for vehicle stability and control.

Electronics and Sensors: Producing advanced electronic components and sensors for modern vehicles.

The medical device industry requires absolute precision and cleanliness. Our services include:

Implants and Prosthetics: Manufacturing biocompatible implants and prosthetics with precise specifications.

Surgical Instruments: Producing high-quality surgical instruments for various medical procedures.

Diagnostic Equipment: Creating reliable components for diagnostic machines and devices.

We leverage our CNC expertise to machine hydrocarbon sensing equipment and components used for accurate volume measurements in oil terminals and ports. Our supply chain is approved for ATEX testing and certification, ensuring the reliability and safety of fuel delivery systems. A significant part of our work for oil and gas clients also involves inspecting machined components, conducting detailed dimensional checks, and performing rigorous testing.

With over 30 years of experience working with European oil and gas industry clients, we fully understand the sector's strict safety and quality standards.

At CNC Precision Engineering, our commitment to excellence drives everything we do. We believe that true excellence is achieved through a combination of precision, innovation, and dedication to our clients’ success.

Our manufacturing facilities are equipped with the latest technology and machinery, ensuring that we can meet the highest standards of precision and efficiency. From advanced CNC machines to sophisticated quality control equipment, our facilities are designed to support the production of high-quality components and assemblies.

Our team of skilled engineers, machinists, and technicians brings a wealth of experience and expertise to every project. We invest in ongoing training and development to ensure that our team stays at the forefront of industry advancements and best practices.

We place our clients at the center of everything we do. Our customer-centric approach means that we work closely with you to understand your needs, challenges, and goals. We are committed to delivering solutions that not only meet but exceed your expectations.

Quality is the cornerstone of our operations. Our quality assurance processes include:

Utilising cutting-edge measurement technologies to ensure precise dimensions and tolerances.

Including mechanical, thermal, and environmental testing to verify product performance.

Ongoing efforts to enhance processes, reduce variability, and increase efficiency.

At CNC Precision Engineering, we are committed to sustainable practices. We strive to minimise waste, optimise resource usage, and implement eco-friendly technologies in our operations. Our goal is to not only excel in precision engineering but also contribute positively to the environment.

We are at the forefront of technological advancements, continuously integrating the latest innovations in engineering and manufacturing. Our commitment to research and development keeps us ahead of the curve, enabling us to provide solutions that are not only precise but also cutting-edge.

Are you ready to experience the unmatched precision and superior results that CNC Precision Engineering can deliver? Contact us today to discuss your project requirements and discover how we can help you achieve your manufacturing goals.

Speak to our friendly team today.

Our precision engineering process is designed to ensure the highest levels of accuracy and quality in every project. Here’s a closer look at how we achieve unmatched precision:

We begin with a thorough consultation to understand your specific needs and requirements. Our team works closely with you to develop a detailed design that meets your exact specifications.

Choosing the right materials is crucial for the success of any project. We have expertise in working with a wide range of materials, including aluminium, stainless steel, carbon steel, and various plastics. Our material selection process ensures that the chosen materials will perform optimally for your application.

Our state-of-the-art CNC machining capabilities allow us to deliver precision-engineered components with exceptional accuracy and efficiency. We utilise the latest technology to handle complex designs, tight tolerances, and a wide range of materials, ensuring optimal performance and durability. Whether it's prototyping, small batch production, or large-scale manufacturing, our advanced CNC solutions cater to diverse industry needs, offering high-quality results every time.