CNC machining has transformed manufacturing with precision, efficiency, and versatility. Our facility, equipped with six advanced CNC machines, delivers high-quality parts across various applications. Explore our capabilities in CNC precision, CNC aluminium machining, CNC milling, and CNC lathing.

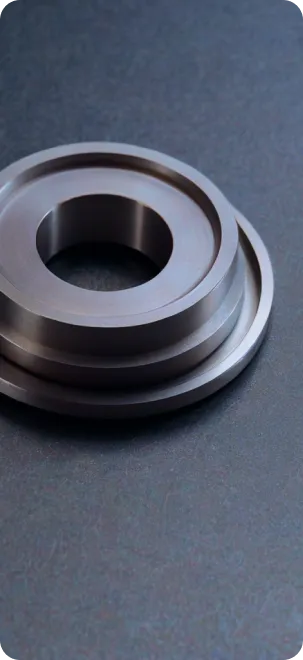

Expertly crafted custom CNC parts tailored to your specifications, ensuring precision and reliability for all your project needs. We are pleased to offer this CNC product to meet your unique requirements with the highest standards of quality.

Our CNC machining services are renowned for their accuracy and efficiency. Utilising the latest CNC technology, we produce high-precision components with complex geometries and tight tolerances. Our capabilities include:

Allows for the creation of intricate parts with high precision.

Ideal for producing cylindrical parts with complex features.

From rapid prototyping to full-scale production runs, we deliver consistent quality and precision.

Our CNC aluminium machining services are designed to produce high-quality aluminium parts with consistent accuracy. We offer:

Tailored to meet your specific requirements.

Efficient production processes for large-scale manufacturing.

Knowledge of a wide range of aluminium grades to ensure optimal performance and durability.

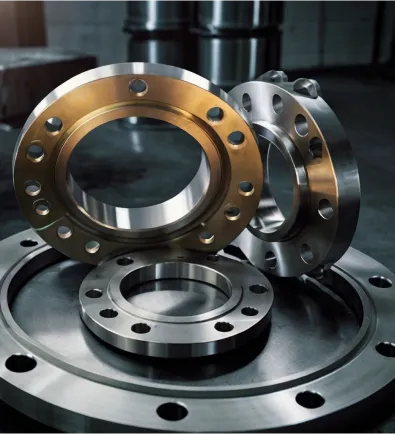

We provide a comprehensive range of flanges for various applications. Our flange manufacturing services include:

Manufactured to meet your specific requirements.

Ensures a perfect fit and reliable performance.

Ability to work with various materials, including stainless steel, carbon steel, and more.

Our expertise in producing spectacle blinds, spades, and spacers ensures that your piping systems can be safely and efficiently isolated. We offer:

Tailored to meet your specific requirements and industry standards.

Ensures accurate dimensions and reliable performance.

Manufactured from high-quality materials for long-lasting use.

Our blanking spades are designed for secure and efficient isolation of pipelines. We provide:

Tailored to meet your specific needs.

Ensuring durability and reliability in demanding environments.

Guarantees accurate dimensions and a perfect fit.

Welcome to our dedicated sales page for top-quality flanges. Whether you are in the oil and gas industry, construction, plumbing, or any other field that requires robust and reliable flanges, you have come to the right place. At CNC Precision Engineering, we are committed to providing high-quality CNC flanges that meet your precise specifications and ensure seamless operations in your projects.

Choosing the right flange is crucial for the success and safety of your project. Here are some compelling reasons to choose our flanges:

Our flanges are manufactured using only the highest quality materials, ensuring durability and long-lasting performance. We understand that flanges are critical components in piping systems, so we make no compromises on the quality of materials used. Our flanges are resistant to corrosion, wear, and high pressures, making them suitable for various industrial applications.

Each flange we produce is a result of meticulous engineering and precision manufacturing. Our state-of-the-art production facilities and stringent quality control processes ensure that every flange meets the highest standards. Our CNC flanges are designed to provide a perfect fit and seal, reducing the risk of leaks and enhancing the efficiency of your piping systems.

We offer an extensive range of flange types to meet the diverse needs of our clients. Our product range includes:

Weld Neck Flanges: Ideal for high-pressure applications, providing a secure connection.

Slip-On Flanges: Easy to install and perfect for low-pressure applications.

Blind Flanges: Used to close the end of a piping system, providing a secure seal.

Socket Weld Flanges: Suitable for small-diameter, high-pressure pipes.

Lap Joint Flanges: Used with stub end fittings, allowing for easy alignment..

Threaded Flanges: Ideal for connecting pipes without welding.

Orifice Flanges: Used for measuring flow rates in piping systems.

We understand that some projects require unique specifications. That's why we offer custom CNC flange manufacturing services. Provide us with your specific requirements, and our expert team will design and produce flanges that meet your exact needs. Our custom flanges ensure you get the perfect solution for your project, no matter how complex.

Our commitment to our clients goes beyond just providing high-quality products. We pride ourselves on offering exceptional customer service. Our team of knowledgeable professionals is always ready to assist you with your flange needs. Whether you need help selecting the right flange or have questions about our products, we are here to help.

Flanges are crucial components used to connect pipes, valves, pumps, and other equipment in piping systems. They provide a secure and leak-proof connection, allowing for easy assembly, disassembly, and maintenance of the piping system. Flanges are typically joined by bolting and sealed with gaskets.

Flanges are used across a wide range of industries and applications, including:

Weld neck flanges are designed for high-pressure applications. They are attached to the pipe by welding the neck of the flange to the pipe, providing a secure and leak-proof connection. Weld neck flanges are ideal for applications where high pressure and temperature are factors.

Slip-on flanges are easy to install and are ideal for low-pressure applications. They are slipped over the pipe and then welded in place, providing a secure connection. Slip-on flanges are commonly used in applications where low pressure and low stress are factors.

Blind flanges are used to close the end of a piping system or a vessel. They provide a secure seal and can be easily removed for maintenance and inspection. Blind flanges are essential components in various industries, including oil and gas, chemical processing, and power generation.

Socket weld flanges are used for small-diameter, high-pressure pipes. They are welded to the pipe by inserting the pipe into the socket of the flange and then welding it in place. Socket weld flanges provide a secure and leak-proof connection, making them ideal for high-pressure applications.

Lap joint flanges are used with stub end fittings and are ideal for applications where frequent disassembly is required. They allow for easy alignment and provide a secure connection. Lap joint flanges are commonly used in industries where maintenance and inspection are frequent.

Threaded flanges are ideal for connecting pipes without welding. They are threaded onto the pipe, providing a secure connection. Threaded flanges are commonly used in low-pressure applications and are easy to install and remove.

Orifice flanges are used for measuring flow rates in piping systems. They are designed with a hole in the center, allowing for the installation of an orifice plate. Orifice flanges are essential components in various industries, including oil and gas, chemical processing, and power generation.

We understand that some projects require unique specifications. That's why we offer custom flange manufacturing services. Provide us with your specific requirements, and our expert team will design and produce flanges that meet your exact needs. Our custom CNC flanges ensure you get the perfect solution for your project, no matter how complex.

Our advanced manufacturing capabilities allow us to produce custom flanges with precision and accuracy. We use the latest technology and equipment to ensure that every flange meets your exact specifications. Our custom flanges are made from high-quality materials and undergo rigorous quality control processes to ensure durability and performance.

We understand that time is critical in your projects. That's why we offer quick turnaround times for our custom flange manufacturing services. Our efficient production processes and experienced team ensure that your custom flanges are delivered on time, without compromising on quality.

Our flanges are designed and manufactured to provide a secure and leak-proof connection, enhancing the safety and reliability of your piping systems. The high-quality materials and precision engineering ensure that our flanges can withstand high pressures, temperatures, and corrosive environments.

Using our flanges in your piping systems can significantly improve efficiency. The secure connection provided by our CNC flanges reduces the risk of leaks and ensures smooth and uninterrupted flow in your systems. This leads to increased productivity and reduced downtime.

Investing in our high-quality flanges can lead to significant cost savings in the long run. The durability and performance of our CNC flanges reduce the need for frequent replacements and maintenance, saving you time and money. Additionally, our competitive pricing ensures that you get the best value for your investment.

Our flanges are manufactured in compliance with industry standards and regulations. This ensures that our CNC flanges meet the highest quality and safety requirements, providing you with peace of mind and confidence in your purchase.

Our extensive range of flange types and custom manufacturing services ensure that we can meet the diverse needs of various industries. Whether you need flanges for high-pressure applications, low-pressure applications, or specialised requirements, we have the perfect solution for you.

Our team of knowledgeable professionals is always ready to assist you with your flange needs. Whether you need help selecting the right flange or have questions about our products, we are here to help. Our expert guidance ensures that you get the best solution for your project.

Our commitment to our clients goes beyond just providing high-quality products. We offer exceptional after-sales support to ensure that you are satisfied with your purchase. If you have any issues or concerns, our team is always available to provide assistance and resolve any problems.

We understand that every project is unique. That's why we offer customised solutions to meet your specific needs. Our custom flange manufacturing services ensure that you get the perfect solution for your project, no matter how complex.

At CNC Precision Engineering, we pride ourselves on offering a vast variety of CNC products that cater to every type of machining need in the UK. Our collection of CNC machines is designed to handle everything from basic operations to complex CNC projects. Whether you’re interested in a mini lathe, a powerful router, or advanced CNC systems, we have the right solution for you. Each CNC product is engineered to ensure precision, delivering top performance with exceptional accuracy in every detail.Our extensive inventory includes various parts, tools, and accessories, allowing you to select the right equipment for your specific business requirements. If you're running a CNC business, our CNC support services, which include CNC training and CNC relocation, will help you maximise productivity and efficiency. Explore our online shop, where you’ll find everything from cutters and tooling kits to sophisticated CNC robot like Fanuc CNC machines that automate processes and enhance your operational capabilities.For those looking to machine materials such as wood and acrylic, we provide tailored solutions that meet your unique requirements, whether you’re utilising mill or board machining techniques. Our advanced software integrates seamlessly with your equipment, facilitating the complexities of machining CNC operations. With the right tools at your fingertips, you can tackle projects of any complexity, ensuring you have everything you need to succeed in your CNC business. Stay informed with our latest articles on CNC projects and innovations and visit our store to discover the latest advancements in CNC products and services.

In the world of CNC precision engineering, understanding the interconnected elements that drive success is essential. CNC systems form the foundation, enabling automated, precise machining. Alongside these systems, CNC businesses are expanding rapidly, responding to diverse industry needs with innovative solutions. Virtual CNC simulators enhance accuracy by allowing machinists to test designs and processes before production, reducing costly errors and material waste. Complementing this are advanced CNC software tools, which streamline everything from design (CAD) to machine control, making complex projects more manageable and efficient. Together, these components are redefining how CNC businesses operate, enhancing both productivity and precision in modern manufacturing.

1. What types of CNC machining services do you offer?

We offer a range of CNC machining services, including precision CNC machining, CNC aluminium machining, CNC milling, CNC lathing, 5-axis machining, and multi-axis turning. Each service is designed to meet high-quality standards for precision, efficiency, and durability

.2. Can I order custom CNC parts?

Yes, we specialise in custom CNC parts tailored to your specifications. Simply provide your requirements, and our team will create high-precision, reliable parts for your project.

3. What materials can you work with for flanges and other products?

We work with a variety of high-quality materials such as stainless steel, carbon steel, and aluminium. Our team will help you select the best material to meet the performance requirements of your project.

4. Do you offer high-volume production?

Absolutely. Our facility is equipped for both prototyping and full-scale production runs, ensuring consistency and precision, whether you need a single prototype or a large batch of components.

5. What are the benefits of using CNC machined flanges?

Our CNC flanges are crafted with precision engineering, ensuring a secure fit, corrosion resistance, and durability. They are ideal for various industrial applications, from high-pressure to low-pressure environments.

6. How quickly can you deliver custom orders?

Our efficient production processes and dedicated team allow for quick turnaround times on custom orders. Delivery times vary depending on project complexity, but we work to ensure on-time delivery without compromising quality.

7. Do you provide support in choosing the right flange or CNC product?

Yes, our knowledgeable team is here to guide you in selecting the best CNC products or flanges for your needs. Contact us with your requirements, and we’ll help you find the right solution.

8. Are your products compliant with industry standards?

Our products are manufactured to meet industry standards, ensuring high quality, safety, and performance across all applications.

9. Do you offer after-sales support?

Yes, we provide dedicated after-sales support to ensure your satisfaction with our products. If you have any issues or questions, our team is here to assist you.

10. How can I place an order for custom flanges or spades?

To place an order, contact our team with your specific requirements. We will provide a tailored quote and guide you through the ordering process.

CNC Precision Engineering is dedicated to providing high-quality CNC flanges that meet your precise specifications and ensure seamless operations in your projects. Our extensive range of CNC flange types, custom product manufacturing services, and exceptional customer support make us the ideal choice for all your flange needs. Whether you are in the oil and gas industry, chemical processing, power generation, water treatment, construction, or any other field that requires robust and reliable flanges, we have the perfect solution for you.

Don't compromise on quality. Choose our CNC Machine and flanges for enhanced safety, reliability, and efficiency in your piping systems. With one goal in mind—providing the best way to meet your machine and flange needs—we invite you to contact us today to learn more about our products and services and let us help you find the perfect flange solution for your project.

For any additional details, we’re here to assist you in making the best choice for your applications.