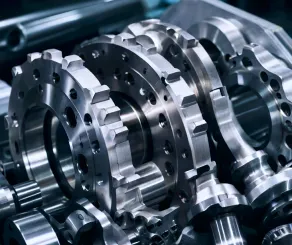

In the world of industrial engineering and manufacturing, flanges are essential components used to connect pipes, valves, pumps, and other fittings, creating a robust piping system. Flanges play a critical role in ensuring the integrity, safety, and functionality of various systems across industries, from oil and gas to chemical processing and automotive manufacturing. These connections are crucial for transporting products efficiently and reliably, which directly impacts the overall results of industrial operations.

In this comprehensive blog, we’ll explore:

A flange is a mechanical component that connects two parts of a piping system, such as pipes, valves, or fittings. Flanges provide a method for joining two sections of pipe together, allowing for easy assembly, disassembly, and maintenance. They come in various sizes and pressure ratings, including the commonly used PN16, which denotes a nominal pressure rating. Flanges are available in various standards, such as BS4504, and are typically bolted together with gaskets in between to ensure a leak-proof seal. A flange product includes valve flanges, tank flanges, while options for stainless flanges or weld flanges provide additional flexibility for different applications. These components can also be detailed with specific SKU numbers to facilitate identification and are often used in conjunction with hoses and press fittings in various industrial processes. Flanges are used in plumbing, water treatment, gas pipelines, all of which contribute to successful results across various sectors.

The surface of the flange where it meets the gasket. The flange face is crucial for ensuring a tight seal.

The hub is the part of the flange that is connected to the pipes or fittings. It can be a welding neck, slip-on, or socket weld design.

Flanges typically have bolt holes around their circumference for bolting two flanges together.

A gasket is placed between the flange faces to create a seal that prevents leaks.

The assembly of two flanges bolted together with a gasket in between is called a flange joint.

Flanges are vital in any system where pipes and fittings need to be connected securely and reliably. They provide several advantages, ultimately leading to improved operational results and efficiency across industries. Flanges made from carbon steel are particularly valued for their strength and durability, while steel flanges are popular for their resistance to corrosion.

Flanges make it easy to assemble and disassemble piping systems and fittings, facilitating maintenance and repairs for various products.

Flanges, when properly installed with a gasket, create a tight seal that prevents leaks, which is crucial in systems carrying fluids or gases.

Flanges allow for flexibility in piping design, making it easier to connect various components and fittings of a system.

Flange joints are designed to withstand high pressures and temperatures, ensuring the safety of the system.

Flanges come in various types, each designed for specific applications and requirements. Understanding the different flange types is essential for selecting the right flange for your project.

The welding neck flange is typically made from a carbon steel and is characterized by its long, tapered hub. This design provides reinforcement and reduces stress on the flange. Welding neck flanges are typically used in critical applications like oil and gas pipelines, chemical processing plants, and refineries.

Key Features: Tapered hub, butt-welded to the pipe, suitable for high pressure and temperature. Applications: Oil and gas, chemical processing, power generation.

Lap joint flanges are used with stub ends and are not welded directly to the pipes or fittings. Instead, the flange can rotate around the pipe, allowing for easy alignment of bolt holes. This makes lap joint flanges ideal for systems where frequent disassembly and reassembly are required. They are commonly used in systems that handle corrosive fluids, where the stub end material can be different from the flange material.

Key Features: Rotatable, used with stub ends, suitable for corrosive environments. Applications: Corrosive fluid systems, pipelines requiring frequent maintenance.

A blind flange is a solid disk used to close off the end of a pipe or vessel. Unlike other flanges, blind flanges do not have a hole for fluid flow. They are used to isolate sections of a piping system for maintenance, testing, or repair. Blind flanges can be easily removed and replaced, making them a practical choice for temporary or permanent pipe closures.

Key Features: Solid disk, used to close off pipe ends, suitable for isolation and maintenance. Applications: Pipe isolation, system maintenance, pressure testing.

The slip-on flange, often crafted from carbon steel, is a flat-faced flange that slips over the pipe and is then welded in place. This type of flange is easier to install than a welding neck flange and is suitable for lower-pressure applications. Slip-on flanges are commonly used in water treatment plants, plumbing systems, and HVAC systems.

Key Features: Flat face, easy installation, suitable for low-pressure applications. Applications: Water treatment, plumbing, HVAC systems.

A hub flange, also known as a weld neck flange, features a tapered hub that gradually increases in thickness from the weld area to the flange face. This design provides reinforcement and reduces stress concentration at the base of the flange. Hub flanges are commonly used in high-pressure and high-temperature applications, such as oil and gas pipelines, chemical processing plants, and power generation systems.

Key Features: Tapered hub for stress reduction, butt-welded to the pipe, suitable for high pressure and temperature. Applications: Oil and gas, chemical processing, power generation.

Socket weld flanges are similar to slip-on flanges but have a recessed area into which the pipe is inserted before being welded. This provides a stronger connection than a slip-on flange and is suitable for small-diameter, high-pressure fittings. Socket weld flanges are often used in chemical processing and hydraulic systems.

Key Features: Recessed area for pipe insertion, strong connection, suitable for small-diameter, high-pressure pipes. Applications: Chemical processing, hydraulic systems, instrumentation.

Threaded flanges have internal threads that allow them to be screwed onto a pipe without welding. This makes them ideal for systems where welding is not possible or practical. Threaded flanges are commonly used in low-pressure applications, such as water supply systems and gas pipelines.

Key Features: Internal threads, no welding required, suitable for low-pressure applications. Applications: Water supply systems, gas pipelines, plumbing.

A flange joint is the assembly of two flanges connected by bolts and separated by a gasket. The flange joint is critical to the integrity of a piping system, as it ensures a leak-proof seal and provides mechanical strength to withstand pressure, temperature, and vibration.

Two flanges are bolted together, with one attached to each pipes or fittings.

A gasket is placed between the flange faces to create a seal that prevents leaks. The choice of gasket material depends on the application, including factors such as pressure, temperature, and the nature of the fluid.

Bolts and nuts are used to tighten the flanges together, compressing the gasket and creating a tight seal.

Proper alignment of the flange joint is essential to ensure a leak-proof connection. Misalignment can lead to gasket failure and leaks.

Flange joints are crucial in any piping system because they provide:

A properly assembled joint flanges ensures a tight seal, preventing leaks that could cause safety hazards, environmental damage, or system failures.

Flange joints provide mechanical strength, allowing the piping system to withstand high pressure, temperature, and vibration.

Flange joints can be easily disassembled, allowing for quick and convenient access to the piping system for maintenance, inspection, or replacement.

The integrity of a flange joint depends on several factors, including:

The gasket material must be compatible with the fluid, pressure, and temperature of the system.

Proper bolt tightening is essential to ensure an even distribution of pressure across the flange joint. Over-tightening or under-tightening can lead to gasket failure.

Proper alignment of the joint flanges is critical to prevent uneven loading on the gasket and potential leaks.

The surface finish of the flange faces can affect the gasket's ability to create a seal. A smooth, clean surface is essential for a leak-proof connection.

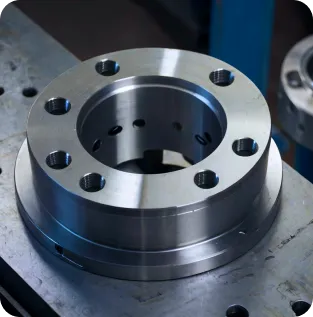

CNC machines can produce flanges with extremely tight tolerances, ensuring that they fit perfectly with other components and fittings in the piping system.

CNC machines can work with a wide range of materials, including stainless steel, carbon steel, alloy steel, and more. This versatility allows for the production of flanges suitable for various industries and applications.

CNC machining provides consistent quality across large production runs, ensuring that every flange meets the same high standards.

CNC machines can produce flanges with complex geometries, including custom designs that may be required for specific applications.

CNC machining is an efficient process that can produce flanges quickly, reducing lead times and ensuring timely delivery to customers.

The CNC machining process for flanges typically involves the following steps:

The flange design is created using CAD (Computer-Aided Design) software and then programmed into the CNC machine.

The finished flange is inspected for accuracy, dimensions, and surface finish to ensure it meets the required specifications.

The appropriate material for the flange is selected based on the application requirements, often choosing between carbon steel and stainless steel.

The CNC machine precisely cuts and shapes the flange from the selected material. This includes drilling bolt holes, shaping the flange face, and machining the hub if applicable.

Depending on the application, the flange may undergo additional finishing processes, such as polishing or coating, to enhance its performance and durability.

In summary, flanges are integral to creating reliable and efficient piping systems across various industrial sectors. By understanding the different types of flanges, their applications, and the benefits of CNC precision manufacturing, you can make informed decisions for your projects. At CNC Precision Engineering, we pride ourselves on producing high-quality of flange product, including valves flanges and weld flanges, tailored to meet your specific needs. Our commitment to precision ensures that every flange, with detailed flanges and SKU identification, is manufactured to the highest standards. Each part is crafted with care to guarantee performance and reliability. For more information on our range of flanges, including stainless options and the latest innovations in hose connections, view our product page and contact us to discuss how we can assist you in achieving optimal results for your piping systems. Don’t hesitate to ask us for the number of different flanges available to meet your needs.

Readers often inquire about the various types of flanges, including welding neck, blind, and slip-on flanges, and their specific applications. Key factors to consider when selecting a flange are material, size, and pressure rating—like PN16. Flange products, such as valve and tank flanges, provide flexibility for different industrial needs. Proper installation is crucial for ensuring a leak-proof seal, as misalignment can lead to failures.

For the latest updates on CNC precision manufacturing, industry insights, and special offers, subscribe to our newsletter! Stay informed about new products, upcoming events, and innovative solutions in flange manufacturing and more. Additionally, explore our website for more valuable resources and information. By following the links, you’ll never miss an update!