At CNC PRECISION ENGINEERiNG, we blend cutting-edge technology with unparalleled expertise to deliver precision-engineered solutions that drive innovation and success across industries.

At

CNC Precision Engineering, we specialise in delivering high-precision CNC (Computer Numerical Control) engineering solutions tailored to meet the unique needs of our clients across various industries.

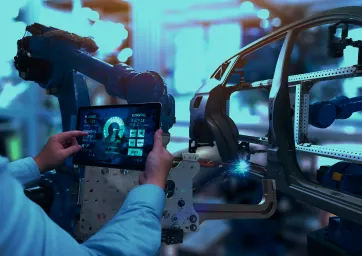

CNC machining is an automated manufacturing process that controls and operates machinery with precision, ensuring consistency and quality in production. It serves as a computer-guided manufacturing and automating tool, utilising a computer numerical control machine (CNC) to enhance efficiency, accuracy and speed in production.

With a commitment to excellence and innovation, we have established ourselves as a trusted partner for precision machining and manufacturing.

We pride ourselves on our ability to produce components that meet stringent specifications. For example, our

CNC machining capabilities enable us to create intricate parts with complex geometries that are essential for modern engineering applications. Another example is our proficiency in producing custom aluminium parts, where we leverage advanced machining techniques and the latest CNC machines to ensure durability and performance.

Our expertise extends across various types of machining processes, including CNC milling, turning, and electrical discharge machining (EDM). Each of these 3 types offers unique advantages, allowing us to cater to a wide range of client needs. We also utilise a variety of specialised tool to achieve precision in our manufacturing processes.

With a commitment to excellence and innovation, we have established ourselves as a trusted partner for precision machining and manufacturing.

Our Philosophy

Our philosophy is rooted in the belief that precision engineering is not just about manufacturing; it’s about creating solutions that empower our clients to succeed. We understand that the

products we manufacture are often critical to our clients' operations, which is why we take a holistic approach to every project. From initial consultation to final delivery, we focus on understanding our clients’ unique challenges and working collaboratively to develop tailored solutions that drive results. We also believe in continuous improvement and staying ahead of industry trends. This commitment to innovation drives us to invest in the latest technology, enhance our skills, and adopt best practices in all aspects of our business. Our team is dedicated to achieving the highest levels of quality, efficiency, speed and automation in everything we do, utilising the best tools available in the market.

Our Mission and Vision

At CNC Precision Engineering, our mission is to lead the industry in precision engineering solutions by leveraging cutting-edge technology and a skilled workforce. We strive to provide our clients with high-quality

products and services that enhance their operations and drive innovation. Our vision is to be recognised as a premier provider of

CNC machining services, known for our commitment to excellence, sustainability, and customer satisfaction. We aim to continually evolve and adapt to the ever-changing market demands, ensuring that we remain at the forefront of the precision engineering sector. By fostering strong relationships with our clients and partners, we are dedicated to creating solutions that not only meet but exceed expectations, contributing to the success of their projects and the advancement of the

industry as a whole.

Our CNC machining services are renowned for their accuracy and efficiency. Utilising the latest CNC technology advanced machines, we produce high-precision components from various workpiece materials with complex geometries and tight tolerances. Our capabilities include:

Allows for the creation of intricate parts with high precision through CNC machining.

From rapid prototyping to full-scale production runs, we deliver consistent quality and precision with every workpiece we process using CNC machining techniques and the right tool.

Our CNC aluminium machining services are designed to produce high-quality aluminium parts with consistent accuracy. We offer:

Tailored to meet your specific requirements using advanced CNC machining.

Efficient production processes for large-scale manufacturing driven by CNC machining.

Knowledge of a wide range of aluminium grades to ensure optimal performance and durability of the finished part or workpiece produced through CNC machining.

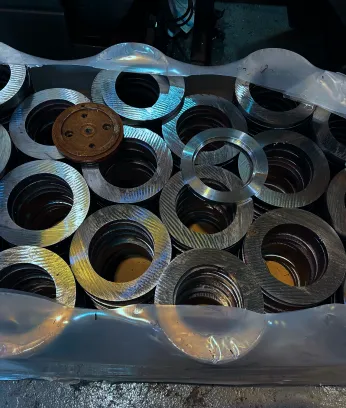

We provide a comprehensive range of flanges for various applications. Our flange manufacturing services include:

Manufactured to meet your specific requirements from different workpieces through CNC machining.

Ensures a perfect fit and reliable performance through precision CNC machining.

Ability to work with various materials, including stainless steel, carbon steel, and more, ensuring the best fit for each part or workpiece created with CNC machining.

Our expertise in producing spectacle blinds, spades, and spacers ensures that your piping system can be safely and efficiently isolated. We offer:

Tailored to meet your specific requirements and industry standards using CNC machining.

Ensures accurate dimensions and reliable performance, showcasing the capabilities of CNC machining and high-quality tool.

Manufactured from high-quality materials for long-lasting use, utilising the advantages of CNC machining.

Our blanking spades are designed for secure and efficient isolation of pipelines. We provide:

Tailored to meet your specific needs with CNC machining.

Ensuring durability and reliability in demanding environments, allowing us to transform raw workpieces into essential part through CNC machining.

Guarantees accurate dimensions and a perfect fit with CNC machining.

Our precision engineering process is designed to ensure the highest levels of accuracy and quality in every project, making sure we meet exacting standards. Here’s a closer look at how we achieve unmatched precision:

Our precision engineering process is designed to ensure the highest levels of accuracy and quality in every project. Here’s a closer look at how we achieve unmatched precision:

Years Experience

High Quality Steel Produced

Project Has Been Completed

Partners Around The World

Reach out to start your CNC project with precision and expertise

Spectacle blinds, also known as figure-8 blinds, are crucial components in piping systems across various industries, including oil and gas...

In the world of industrial piping systems, where the safe and efficient management of fluids and gases is critical, the role of flow control components cannot be overstated. Among these...

At CNC Precision Engineering, we offer a diverse range of precision engineering solutions that cater to various industries. Our services encompass three main types of machining processes: CNC milling, CNC turning, and electrical discharge machining (EDM). Each type has its unique strengths and applications, allowing us to tailor our approach to meet the specific needs of our clients. In addition to the machining processes, we also focus on the materials used in our projects, including casting and metal, ensuring that we select the best options for durability and performance while considering the overall cost. Our skilled team utilises advanced tools and cutters and our design capabilities enable us to create custom solutions that are made to not only meet but exceed industry standards, providing our clients with the precision and quality they expect from a trusted engineering partner. By combining our expertise in materials and design with advanced machining techniques, we deliver high-quality part or product that drive success across various applications, including injection molding and sheet metal fabrication.

In this section, we delve into the fundamentals of CNC, exploring how it serves as the backbone of our precision engineering services. CNC, or Computer Numerical Control, refers to the automated manufacturing process that controls and operates a CNC machine with high precision. This tech enables us to produce components with intricate designs and tight tolerances, significantly enhancing efficiency and accuracy in production. By leveraging advanced software solutions, we can create parts that meet the unique requirements of our clients across various industries, ensuring quality and reliability in every project. Our expertise also extends to various processes, including extrusion, which allows us to cater to a diverse market and provide tailored solutions.

At CNC Precision Engineering, we are committed to delivering exceptional precision engineering solutions that meet the diverse needs of our clients. Our dedication to quality, innovation, and efficiency sets us apart in the industry. We understand that the CNC products we manufacture are crucial to our clients' success, and we strive to foster strong partnerships built on trust and excellence. With our extensive experience and expertise in various machining processes, we provide clear instruction to ensure that each project is executed to the highest standards, making us well-equipped to handle a wide range of engineering challenges.

We invite you to explore our related services and discover how we can collaborate to achieve your manufacturing goals. For further information, please follow the links to our services, and if you have any questions or would like to discuss your project further, please don’t hesitate to Contact Us. We look forward to hearing from you!

1. What is CNC Precision Engineering?

CNC Precision Engineering is a specialist provider of high-precision CNC (Computer Numerical Control) engineering solutions. Our expertise lies in utilising advanced CNC machining processes to create custom-engineered components for various industries, ensuring high levels of accuracy and reliability.

2. What industries does CNC Precision Engineering serve?

We serve a diverse range of industries, including automotive, aerospace, energy, medical, and industrial manufacturing, providing precision components that meet strict specifications.

3. What services does CNC Precision Engineering offer?

Our services include CNC machining (CNC milling, CNC turning, and CNC EDM), custom CNC aluminium machining, CNC flange manufacturing, and the production of critical piping components like spectacle blinds, spades, and spacers. Each service is designed to meet the unique requirements of our clients.

4. What materials does CNC Precision Engineering work with?

We work with a wide variety of materials, including aluminium, stainless steel, carbon steel, and other high-quality metals. This material versatility ensures durability and performance for each component we produce.

5. How does CNC machining enhance precision and efficiency?

CNC machining uses computer-guided tools to control machining processes with exceptional accuracy, enabling the production of complex parts with tight tolerances. This automation increases efficiency, reduces errors, and allows for high-volume production without compromising quality.

6. Can CNC Precision Engineering handle custom projects?

Yes, we specialise in custom projects. Our team collaborates with clients to design and produce bespoke components that meet specific requirements, whether for small prototypes or large-scale production.

8. What is the process for starting a project with CNC Precision Engineering?

To begin, contact us with your project details. We’ll conduct an initial consultation to understand your needs, followed by material selection, design, and production using advanced CNC machining techniques. Our team will guide you through every step to ensure your project is executed to the highest standards.