Spectacle blinds, also known as figure-8 blinds or blinds spades, are crucial components in piping systems across various industries, including oil and gas, petrochemical, chemical processing, and power generation. This device is used to isolate a section of a pipeline or completely block off a pipe, ensuring safety, operational efficiency, and the ability to perform maintenance without shutting down entire systems. Given their critical role, the manufacturing of spectacle blinds requires precision engineering and the use of advanced technologies like CNC (Computer Numerical Control) machining to ensure high-quality, reliable products that meet the stringent standards of these demanding industries. The design of these blinds often includes a central ring that provides added structural integrity and pressure resistance, along with a central spacer that helps maintain the correct alignment between flanges.

This page will explore the importance of spectacle blinds, the benefits of using CNC machining in their production, and why our company is the ideal choice for meeting your spectacle blind needs. By leveraging advanced CNC technologies, we ensure that each spectacle blind we produce is built to the highest standards of quality and performance.

Spectacle blinds are mechanical device that consist of a metal disc welded to a spacer, resembling a pair of eyeglasses, hence the name "spectacle blind". This assembly is typically installed between two flanges in a pipeline, secured with bolts. The spectacle blind can be rotated to either block (blind side) or allow (open side) flow through the pipe, depending on the operational requirements. They work closely with a valve, a spacer and blind spades to control fluid flow effectively.

Spectacle blinds play a crucial role in piping systems across various industries, including oil and gas, petrochemical, chemical processing, and power generation. This device is essential for isolating sections of a pipeline, allowing for maintenance work without shutting down entire systems. Additionally, spectacle blinds are designed to work seamlessly with various gaskets and flanges to ensure leak-proof seals, enhancing safety and operational efficiency. Moreover, the proper selection and installation of gaskets are critical to the performance of spectacle blinds, as they prevent leaks and ensure the integrity of the piping system. In high-pressure applications, choosing the right type of gasket can significantly impact the safety and reliability of the system. This is why understanding the characteristics of different gaskets and their compatibility with spectacle blinds is essential.

Spectacle blinds must be manufactured with tight tolerances to ensure a perfect fit between flanges and prevent any leakage. CNC machining allows for precise control over dimensions, including diameter, ensuring that each blind meets exact specifications.

The materials used in spectacle blinds must withstand high pressures, temperatures, and corrosive environments. Precision engineering ensures that the material properties are maintained throughout the manufacturing process, preventing weaknesses that could compromise performance. The face of the blind must be properly designed to handle the stress of various applications.

In critical applications, such as in the oil and gas industry, the reliability of spectacle blinds is non-negotiable. Precision engineering ensures that these components operate flawlessly, providing consistent performance over their lifespan.

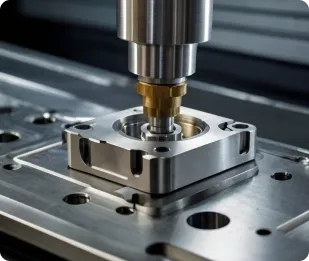

CNC machining is a manufacturing process that uses computerised controls to operate machinery, such as lathes, mills, and grinders, with high precision. This technology is ideal for producing spectacle blinds because it offers the accuracy, consistency, and efficiency required to meet the stringent demands of a wide range of industries. The precise machining of the ring components, flanges and bolts in spectacle blinds ensures that they maintain their effectiveness in high-pressure situations. The diameter of the machined components is also controlled for optimal performance.

CNC machines operate with micron-level precision, allowing for the exact shaping and finishing of spectacle blinds. This level of accuracy ensures that each blind fits perfectly within the piping system, providing reliable isolation and flow control.

CNC machining ensures that every spectacle blind produced is identical to the last, regardless of the complexity of the design. This consistency is crucial for maintaining the integrity of piping systems, especially in large-scale operations where multiple blinds are used.

CNC machines can operate continuously with minimal downtime, enabling the efficient production of spectacle blinds in large quantities. This efficiency translates to shorter lead times and lower costs for our customers.

CNC machining allows for easy customisation of spectacle blinds to meet specific requirements. Whether it's adjusting the dimensions, adding features, or selecting a specific material, CNC technology enables us to tailor our products to your needs and place them within your piping system.

CNC machines can work with a wide range of materials, including carbon steel, stainless steel, duplex steel, and other alloys commonly used in spectacle blinds. This versatility ensures that we can meet the demands of different applications and environments.

At CNC Precision Engineering, we pride ourselves on our state-of-the-art CNC machining capabilities. Our facilities are equipped with the latest CNC technology, operated by a team of skilled engineers and technicians who ensure that every spectacle blind we produce meets the highest standards of quality and precision.

The material selection for spectacle blinds is critical to their performance, especially in harsh environments such as oil and gas pipelines. The right material ensures durability, resistance to corrosion and pressure, and overall reliability.

Spectacle blinds are made from materials chosen for their durability and performance. Common options include stainless steel for strength and corrosion resistance, aluminium for its lightweight and wear-resistant properties, and high-performance alloys or composites for flexibility and strength-to-weight ratios. The material selection depends on the specific application, including pressure, temperature, and environmental factors.

CNC machines can work with a wide range of materials, including carbon steel, stainless steel, duplex steel, and other alloys commonly used in spectacle blinds. This versatility ensures that we can meet the demands of different applications and environments.

When it comes to the production of spectacle blinds, not all manufacturers are created equal. At CNC Precious Engineering, we combine advanced CNC machining technology with a commitment to quality and customer satisfaction, ensuring that our spectacle blinds meet the highest standards of performance.

With years of experience in the industry, our team has the expertise to understand the unique challenges of your application and deliver solutions that meet your exact needs. We have worked with clients across various industries, providing them with high-quality spectacle blinds that enhance the safety and efficiency of their operations.

Quality is at the core of everything we do. Our spectacle blinds undergo rigorous testing and inspection processes to ensure they meet the required standards and specifications. We are committed to delivering products that exceed your expectations in terms of performance, durability, and reliability, especially in their compatibility with different types of gaskets. Every gasket we use is carefully selected to ensure optimal performance, including the specific requirements of spacers spectacle, flanges spectacle, flange spectacle, blinds spectacle, valves spectacle, position spectacle, and spectacle flanges.

Our investment in the latest CNC machining technology allows us to produce spectacle blinds with unmatched precision and consistency. This technology enables us to handle complex designs and tight tolerances, ensuring that every product we deliver is of the highest quality. Our CNC machining process also allows for precise fitting of gaskets, contributing to a secure seal.

We understand that each application is unique, which is why we offer customised solutions tailored to your specific requirements. Whether you need a particular material, size, or design, we can accommodate your needs and deliver spectacle blinds that fit seamlessly into your piping system and place them effectively in your setup. This includes offering various gasket options to match your system’s specifications.

We know that timing is crucial in your operations. Our efficient production processes and streamlined supply chain management ensure that your spectacle blinds are delivered on time, every time. We work closely with our clients to meet their deadlines and keep their projects on track.

While we never compromise on quality, we are committed to offering our products at competitive prices. Our efficient manufacturing processes, combined with our expertise in sourcing materials, allow us to provide high-quality spectacle blinds at a cost that delivers value for money.

Spectacle blinds are used in a wide range of industries, each with its own specific requirements and challenges. Understanding the applications of spectacle blinds in different sectors can help you choose the right product for your needs. The use of a properly designed ring, spacer and blind spades is essential in preventing leaks and maintaining pressure in these applications. In these applications, the key to effective isolation and maintenance is the correct selection and installation of spectacle blinds.

In the oil and gas industry, spectacle blinds are essential for isolating sections of pipelines during maintenance, inspection, or emergency situations. These components must be robust and capable of withstanding high pressures and corrosive environments.

Applications:

Materials:

Stainless steel, duplex steel, and Inconel are commonly used for their corrosion resistance and strength. The use of position spades and bolts is also essential in ensuring correct alignment during installations.

Regular maintenance of spectacle blinds is essential for their longevity and operational efficiency in piping systems. Routine inspections should focus on key components such as gaskets, flanges, and bolts, ensuring they are secure and functioning properly. Proactively addressing wear and tear can prevent disruptions in operations. Additionally, maintaining sealing rings in good condition is vital for effective isolation and leak prevention. Overall, proper maintenance enhances safety and reliability across various industrial applications.

In the context of piping systems, the integration of spectacle blinds with the correct types of flanges is essential. Ensuring that the piping layout accommodates the use of spectacle blinds can greatly enhance the operational efficiency of the entire system. The careful selection of flanges and the configuration of piping must also account for the potential need for maintenance access to spectacle blinds.

Ring plays a crucial role in the sealing effectiveness of spectacle blinds. The proper use of sealing rings ensures that the connection between the spectacle blind and the flanges is secure, preventing leaks and maintaining pressure integrity. Regular inspection of these rings is necessary to ensure they are in good condition and can provide the required sealing performance.

In summary, spectacle blinds are vital components in various piping systems. Their proper integration with gaskets ensures effective sealing and safety, making them indispensable in critical applications. At CNC Precision Engineering, we pride ourselves on our ability to deliver high-quality spectacle blinds tailored to your needs, complete with the right gaskets to ensure optimal performance. We are committed to excellence, from our studbolts spectacle used for secure installations to our understanding of local regulations within the Republic to ensure compliance and quality. Data from our extensive industry experience supports our approach to delivering reliable products that prevent blocked pipelines.

For more information or to discuss your specific requirements, please contact us. Our team of experts is here to assist you with any queries and provide you with the best solutions for your piping needs.