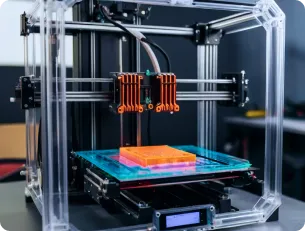

3D printing is a manufacturing process that creates three-dimensional objects by layering material in successive layers until the desired shape is achieved. Unlike traditional subtractive manufacturing methods, where material is removed from a solid block to create a part, 3D printing is an additive process that builds objects layer by layer. This technology allows for the creation of complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods.

The 3D printing process begins with a digital design file, typically created using Computer-Aided Design (CAD) software. This file is then sliced into thin layers, which the 3D printer reads as instructions for building the object. The printer deposits material layer by layer, following the design specifications, until the entire object is complete.

3D printing has a wide range of applications across various industries, from rapid prototyping and product development to custom manufacturing and medical implants. Below are some of the key applications of 3D printing:

One of the most common applications of 3D printing is rapid prototyping. Engineers and designers use 3D printing to quickly produce prototypes of new products, allowing them to test form, fit, and function before moving to mass production. This significantly reduces the time and cost associated with product development.

In the automotive industry, 3D printing is used for producing prototypes, tooling, and even end-use parts. It enables automakers to quickly iterate on designs and produce custom parts for high-performance vehicles.

From fashion and jewelry to household items and electronics, 3D printing is being used to produce a wide range of consumer goods. The technology allows for greater customisation and faster production cycles.

3D printing allows for the creation of custom parts and products tailored to specific needs. This is particularly useful in industries like healthcare, where custom implants and prosthetics can be printed to match a patient’s unique anatomy.

Educational institutions and research facilities use 3D printing to teach students about design and manufacturing processes and to conduct research in fields such as materials science, engineering, and biology.

The aerospace and defense industries leverage 3D printing to produce lightweight, high-strength components that meet strict performance requirements. 3D printing allows for the creation of complex geometries and integrated parts, reducing the need for multiple components and assembly.

3D printing has made significant inroads into the healthcare industry, with applications ranging from custom implants and prosthetics to surgical guides and even bioprinting. The ability to create patient-specific solutions is a major advantage in the medical field.

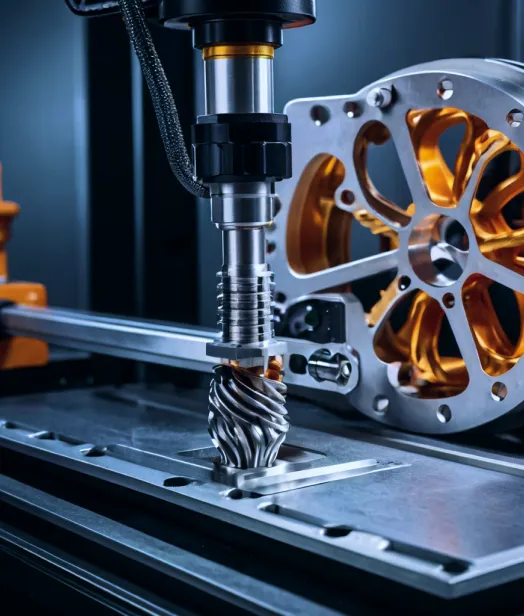

While 3D printing and CNC machining are often seen as competing technologies, they are actually complementary and can be used together to achieve optimal results. CNC (Computer Numerical Control) machining is a subtractive manufacturing process that involves the removal of material from a solid block (known as the workpiece) to create a part. This process is known for its precision, accuracy, and ability to work with a wide range of materials, including metals, plastics, and composites.

While CNC machining and 3D printing serve distinct purposes within the manufacturing landscape, understanding their key differences can help you determine the best approach for your specific needs. Below are the main distinctions:

Subtractive process where material is removed to create the part.

Can work with a wide variety of materials, including metals, plastics, and composites.

Known for high precision and tight tolerances, making it ideal for parts that require exact dimensions.

Best suited for parts with simpler geometries or that require high precision.

Economically viable for both low and high production volumes.

Additive process where material is added layer by layer to build the part.

Typically uses materials such as thermoplastics, resins, and certain metals.

Generally offers lower precision than CNC machining, though advancements are being made to improve accuracy.

Excels in producing complex geometries, including hollow structures and intricate designs.

Ideal for low-volume production, prototyping, and custom manufacturing.

3D printing is often used for rapid prototyping, allowing designers to quickly iterate on designs. Once the design is finalised, CNC machining can be used to produce the prototype in the final material with the required precision.

CNC machining is used to create high-precision molds, dies, and tooling. 3D printing can be used to produce custom jigs and fixtures that help in the assembly process.

For complex geometries that are difficult to machine, 3D printing can produce the part, which is then finished or refined using CNC machining to achieve the desired surface finish and tolerances.

Some advanced manufacturing systems combine CNC machining and 3D printing in a single machine, allowing for the creation of parts that benefit from both processes.

Precision engineering plays a crucial role in the development and application of 3D printing technology. Precision engineering involves the design and manufacturing of components and systems with extremely tight tolerances and high accuracy. In 3D printing, precision engineering ensures that the printer accurately follows the design specifications, resulting in parts that meet the required dimensions and performance criteria.

Precision engineering ensures that 3D printers can produce parts with high accuracy, minimising deviations from the intended design.

Precision engineering contributes to the repeatability of the 3D printing process, ensuring that each part produced is consistent with the others.

Precision engineering ensures that the material is deposited accurately and uniformly, which is especially important for high-performance parts.

Precision engineering affects the surface finish of the printed parts, which is important for applications where aesthetics or smoothness is critical.

Recent advances in precision engineering have led to improvements in 3D printing technology, including:

Advances in precision engineering have enabled 3D printers to achieve higher resolutions, allowing for the production of parts with finer details and smoother surfaces.

Improvements in material handling and deposition have resulted in better control over the properties of the printed parts, such as strength, flexibility, and thermal resistance.

Precision engineering has contributed to faster printing speeds, reducing the time required to produce parts without compromising quality.

Hybrid systems that combine 3D printing with CNC machining are becoming more common, allowing manufacturers to take advantage of both technologies in a single process.

The future of 3D printing in precision engineering and CNC machining looks promising, with ongoing advancements in technology leading to new applications and capabilities. Here are some trends and developments to watch for:

The ability to print with multiple materials in a single process is becoming increasingly important for producing parts with varying properties, such as stiffness, flexibility, or conductivity. This capability is particularly valuable in industries such as electronics, where components may need to combine different materials to achieve specific functions.

Ongoing improvements in precision engineering are leading to 3D printers that can produce parts with higher accuracy and at faster speeds. This is making 3D printing more viable for mass production and high-precision applications.

While plastic and resin-based 3D printing are common, metal 3D printing is rapidly advancing. Metal 3D printing allows for the production of strong, durable parts with complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This is particularly useful in aerospace, automotive, and medical applications.

Advances in 3D printing technology are enabling the production of larger parts and structures. This is particularly relevant in industries such as construction, where 3D printing can be used to create building components or even entire structures.

3D printing is increasingly being integrated into digital manufacturing workflows, where design, prototyping, and production are all managed digitally. This integration allows for greater flexibility, customisation, and efficiency in the manufacturing process.

3D printing is a transformative technology reshaping the manufacturing landscape. From rapid prototyping to custom manufacturing, it offers unique advantages that complement traditional CNC machining and precision engineering. As the technology evolves, it will increasingly play a crucial role in producing complex, high-precision parts across various industries. With advanced 3D printing machines and CNC equipment, manufacturers can achieve greater innovation, efficiency, and customisation in their processes. Whether you're in aerospace, automotive, healthcare, or consumer goods, 3D printing can help you produce high-quality, complex parts that meet today’s market demands.

If you're interested in exploring how 3D printing CNC machines can elevate your manufacturing capabilities, or if you need high-precision parts for your next project, CNC Precision Engineering offers a full range of CNC machining and 3D printing services. Contact us today to learn more about how we can help you achieve your manufacturing goals.